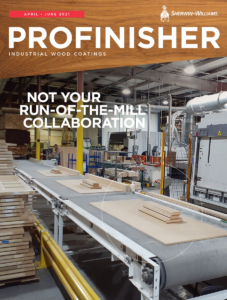

NOT YOUR RUN-OF-THE-MILL COLLABORATION

Millwork 360 and Sherwin-Williams have a long history of working together, positioning the two companies for continued growth in the future.

As a testament to its products and services, Sherwin-Williams remained a constant coatings supplier for Mike Williams, even as he worked for three different companies over the past 24 years. He continues to do business with the coatings company on a daily basis as the general manager of Millwork 360.

CUSTOMIZED PRODUCTS

Millwork 360, located in Tampa, Florida, prioritizes quality in their products, producing custom mouldings and doors for high-end commercial and residential markets. These millwork

pieces are sold directly to lumber yards and dealers who know they’ll receive high-quality products, on-time delivery and exceptional customer support with every purchase.

Brian Baines has only been the sales rep for Millwork 360 for three years, but he and Williams have known each other for much longer, from when Baines worked in the millwork industry himself. Now, working together, Baines has witnessed first-hand how Williams emphasizes quality more than anyone – focusing on continuous improvement for the company’s products.

Millwork 360 has three major product lines: custom, made-to-order mouldings, entry doors and interior doors. To meet customer needs, Millwork 360 offers design flexibility across its entire product offering.

“No matter what request our customers receive from the architect or contractor they’re working with, they know they can give it to us, and 95% of the time we can supply the one-off product,” said Williams. “The flexibility and versatility of our manufacturing is a big advantage.”

Read the entire article here.